Understanding The Role Of Neutral Earthing Resistors In Electric Transformer

Neutral earthing resistors (NERs) are important parts of electrical systems. They are necessary for safety and stability.

These parts are important for electric transformers. They can help control fault current well.

NERs are often neglected, yet they are necessary. Protecting the equipment from damage due to ground faults.

Controlling the size of the fault current, NERs guarantee the system’s stability. This is important for dependable power distribution.

NERS are installed between the neutral point of the transformer and the ground. And this kind of location is important.

They improve electrical safety and reduce the risk of fires. They can also help prevent damage to equipment.

NERs need to be understood by electrical engineers and techs. Helps with creating safe systems. This article talks about how NERs work in transformers. And it shows what they can do and how good they are.

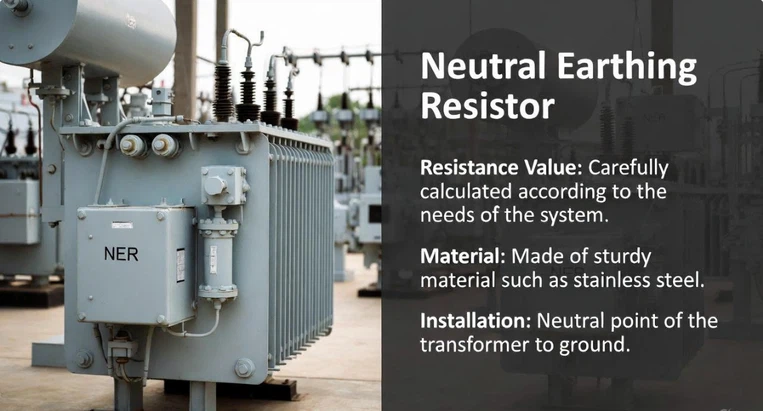

What Is A Neutral Earthing Resistor?

Neutral earthing resistor (NER) is an important part of the electrical system. It limits the fault current through its connection between the neutral point of a transformer and the ground.

The NERs are meant to control the size of the fault current. These currents need to be limited so that the equipment can be protected and stability maintained.

NERs are generally made of resistive materials such as stainless steel and have a certain level of resistance. The value is determined by the system requirement. NERs are commonly found in systems that do not ground the neutral. They become important for different industrial uses.

Key Characteristics Of NERs:

· Resistance Value: Carefully calculated according to the needs of the system.

· Material: Made of sturdy material such as stainless steel.

· Installation: Neutral point of the transformer to ground.

To conclude, it is important to know the function and features of NERs. They greatly help make electrical systems last longer and safer.

Why Electrical Earthing Is Essential For Transformers

Electrical earthing offers a secure route for fault currents within power systems. Safety and dependability of transformers and linked devices.

Earthing keeps the system stable when there’s a problem. It makes sure that any extra current gets safely sent to the ground.

Transformers work at high voltage. Good earthing is needed to prevent serious harm caused by electrical faults. Also, it’s important for safety reasons. Reduces risk associated with equipment failure, fire, and electric shock.

Benefits Of Electrical Earthing:

Safety: Reduce the chance of getting shocked by electricity and catching fire.

Protection: Protects the equipment from damage.

Reliability: To make sure that the system is stable and efficient.

In short, Electrical Earthing is a necessary part of the modern power system. Good earthing strategies improve how long transformers last and make them safer. Understand what it does, so we can build better electric grids.

How Neutral Earthing Resistors Work In Electric Transformers

Neutral earthing resistors (NERs) are part of the transformer’s safety system. They are set up between the transformer’s neutral point and the ground. This position can help control fault current when there is an electric fault.

Under normal circumstances, NERs do not play much of a part. They mainly work during a fault. These events restrict the amount of fault current that can flow through the neutral point.

NERs control fault currents so as to avoid the possible harm to transformers and other apparatus. Limited current prevents the components from getting overloaded when there is a fault. It lowers the chance of getting too hot and burning out. NERs help reduce transient overvoltages. Overvoltages happen due to faults. By reducing them, NERs safeguard the delicate electronics inside the system.

Functions Of Neutral Earthing Resistors:

Fault Limiting: Controls the size of the fault current.

Equipment Protection: Avoids equipment damage caused by large current.

Overvoltage Reduction: Reduces transient overvoltages.

System Stability: Stable operation during faults.

Their job isn’t over once they’ve protected. NERs give a safe way for fault currents to flow, which helps make power systems more reliable. This means that there will be less chance of system failure and a longer life for the system. To get all the good things from them, you have to understand how they work.

Key Functions And Benefits Of Neutral Earthing Resistors

Neutral earthing resistors (NERs) have many important advantages for electrical systems. They are crucial for limiting fault currents which improves safety and equipment reliability.

A major benefit is safeguarding transformers and other key infrastructure. Controlling fault currents can prevent damage from occurring, which would otherwise require expensive repairs. They provide an affordable way to deal with possible electrical problems.

And NERs also make the system more stable. Control the size of fault current so that it can still work steadily when there is a problem. It is important for the power generation, transmission and distribution systems, and NERs can also reduce the risk of fire and electric shock. They moderate fault currents which reduces the likelihood of serious electrical dangers. And it protects the equipment as well as the people.

Key Functions And Benefits:

Fault Current Limitation: Protecting equipment from excessive current.

Improved stability: Keeps the system reliable when there’s a problem.

Fire and shock prevention: It reduces the risk of fire and electric shocks caused by electrical malfunctions.

Cost efficiency: Provides a cost-effective solution for managing faults..

Also, NERs make it simple to spot and separate electrical problems. It makes the maintenance process easier. Faults are found fast, so fixes happen quicker and better.

In short, deploying NERs greatly improves electrical safety and system performance. They are incorporated into the electrical systems to

ensure that they are effective and long-lasting. NERs can be used effectively, which leads to less downtime and a more reliable system.

Types Of Neutral Earthing Resistors And Their Applications

There are different kinds of neutral earthing resistors (NERs). Each type has its own particular uses and places. It’s important to know about these types so that we can pick out the correct NER for any given system.

High-resistance grounding (HRG) resistors are another kind. HRG resistors are commonly found in industry. It can reduce the fault current, but still allow the fault to be detected.

Low resistance grounding (LRG) resistors are also a kind of it. These are generally employed in systems that can tolerate higher fault currents. LRG resistors are found in places where fast fault clearing is necessary. Liquid-type resistors are another kind. These resistors use electrolytes to handle fault currents. They work well with high current situations.

Types Of Neutral Earthing Resistors:

High Resistance Grounding (HRG) Resistors: Good for controlling fault currents.

Low Resistance Grounding (LRG) resistors: for high current systems.

Liquid-Type Resistors: Good at handling big currents.

Each one has its own uses and advantages. It depends on what your system needs, how much electricity is flowing through it, and what

kind of work you want it to do. Power plants, manufacturing, utilities, choosing the right resistor matters for best results.

Selection Criteria: How To Choose The Right Neutral Earthing Resistor

Selecting the appropriate NER is important for the stability and safety of the system. There are several things that need to be taken into account during this decision making process.

Firstly, we should check the system’s voltage and fault current. These parameters determine the value of the resistor as well as its power rating. Proper sizing guarantees that the NER will limit the current without interfering with the system operation.

Then evaluate the environmental circumstances under which the NER will operate. Humidity, Temperature, Corrosive Elements, etc. Physical environment affects the resistor’s longevity and efficiency; material choice matters too. Different applications may need resistors that are made out of stainless steel, cast iron, or even liquids. The selected material needs to be reliable and economical.

Key Considerations For NER Selection:

System Voltage & Fault Current: Decide the necessary resistance and power.

Environmental Conditions: Assess temperature, humidity, and exposure dangers.

Material: Select according to specific operational requirements and budget.

Thoughtful selection results in good NER performance and makes the electrical system safer. NERs that have been properly selected will prevent damage and reduce downtime during faults.

Installation And Maintenance Best Practices

Neutral earthing resistors (NERs) should be installed correctly to get all of its benefits. Placement and connection need to follow the system’s specifications and safety rules.

Use qualified staff for the installation. Skilled technicians make sure that everything is connected properly and that all parts work well with each other.

Routine maintenance is needed for NER to work well. Regular checks can find signs of wear and tear so that repairs can be made on time and everything works best. Good care has some important parts. Technicians have to check for physical damage and corrosion at times. Check the connection, measure the resistance value of the resistor.

Essential Maintenance Practices:

Regular Visual Inspections: Check for any signs of damage or corrosion.

Resistance Testing: Confirm that the resistor meets the necessary standards.

Check the connection: Make sure that all the electrical connections are firmly connected.

Following good practices for installing and maintaining NERs can help organizations increase how long their NERs last. Diligence leads to continuous electrical safety and reduces the chance of sudden system failures.

Common Issues And Troubleshooting Tips

Although they are reliable, neutral earthing resistors (NERs) may experience some problems occasionally. Overheating, wrong resistance value and broken parts are some of the common ones. These problems can have a negative impact on the performance of the system if they are not dealt with quickly.

Overheating is usually due to too much fault current or bad ventilation near the NER. Making sure there’s good airflow and changing the resistance value can fix this problem. Another common problem is wrong resistance values. Inaccurate resistance levels may occur because of aged materials or improper installation. Regular tests can keep the right resistance settings, stopping more problems.

Troubleshooting Tips:

Check for overheating: Make sure there’s good airflow and watch the current.

Test resistance values: Check and adjust when necessary.

Check for physical damage: Look for signs of wear or corrosion.

By solving these common problems, technicians can make NER systems more reliable and useful. Correct diagnosis and handling ahead of

time is important for keeping electrical safety and the system steady.

Safety Considerations And Regulatory Compliance

When using neutral earthing resistors (NERs), safety has to come first. Correct installation guarantees that systems run inside safe boundaries, lowering dangers for machines and people. Poor installation or upkeep of NERs may create dangerous situations that harm the system’s dependability.

Also comply with electrical codes and standards. Different regulatory bodies give rules to make sure things are safe and work well. Following these regulations keeps operations safe and prevents possible legal problems. The key areas to comply with are selection, installation, and regular testing. Keeping track of these activities is also necessary for audits and inspections. Compliance guarantees that the NERs do what they were meant to do well.

Key Safety And Compliance Practices:

Follow the manufacturers’ guidelines for correct installation and use.

Observe local and national codes: keep track of any changes in the standards.

Regular Safety Audits: Do regular checks and write down what you find..

Safety and compliance as the priority, operation will remain safe and efficient, safeguarding important electrical facilities.

The Future Of Neutral Earthing Resistors In Power Systems

The function of neutral earthing resistors (NERs) is changing as power systems get better. As we add more renewable energy sources, we need good, dependable ways to ground things. NERs are adjusting to such changes, making sure that new difficulties are tackled by strong solutions.

And technological advances too. Materials and designs innovations improve NERs’ efficiency and adaptability. With power grids becoming increasingly complex, NERs need to have more flexibility to fit different system needs. Looking forward, NERs will still be important for electrical safety and stability. They can lessen problems and make the system stronger, so they will be important parts of building better and more dependable power systems that last longer. These improvements are leading to safer and more effective energy systems.

Conclusion: The Critical Role Of NERs In Electrical Safety And Reliability

Neutral earthing resistors are important for improving electrical safety and system reliability. Controlling the fault current can prevent the transformer and other equipment from being damaged seriously. They are necessary parts of today’s electrical systems, and also help keep the flow of electricity steady. They help stop possible dangers and make sure that power networks work smoothly. Therefore, their importance for both safety and efficiency cannot be overemphasized. NERs will remain an important part of the ever-changing world of electrical engineering.