Jiangsu Yawei Transformer Co.,Ltd. is one of the leading manufacturers and suppliers of power transformers in China. Please feel free to buy high quality power transformers from our factory. Customized orders are welcome.

Yawei 110kV 230 kV transformers are designed and manufactured according to international standard.

1. GB 6451 Specification and technical requirements for oil-immersed power transformers;

2. IEC 60076 Power Transformers;

3. AS NZS 60076 Power Transformers;

4.CSAC88-16 Power Transformers;

5. ANSI/IEEE C57.12.00 IEEE Standard for General Requirements for Liquid-Immersed Distribution, Power, and Regulating Transformers;

6. GOST R 52719 Power Transformers – General Specifications;

7. EN60076 Power Transformes

8. Local After-Sales Services In North America South America, and other regions respond to your needs within 24 hours. etc, the power ratings are up to 300 MVA, and for voltages up to the highest insulation class of 900 kV.

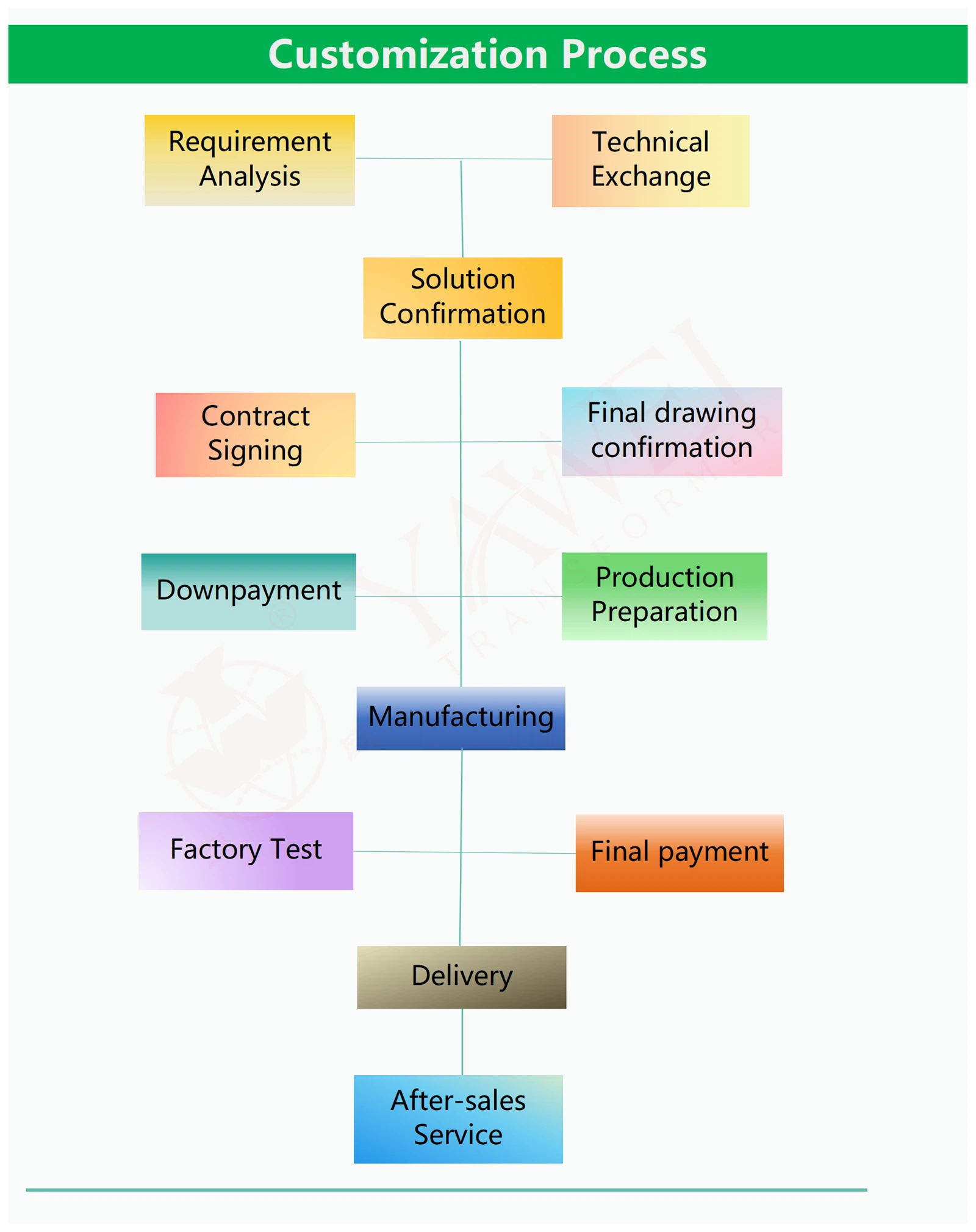

How To Oem/Customization?

The customization process for 110KV and 220KV large transformers is a complex and intricate process that covers multiple stages from requirement analysis to product delivery. The following is a general customization process:

How We Started

REQUIREMENT ANALYSIS

Requirements collection: analyzes and determines the general model, specifications, technical parameters, and usage environment of the required transformer based on the power system requirements.

Assessment of Requirements: Evaluate the collected requirements to ensure technical feasibility and economic rationality

TECHNICAL EXCHANGE

Technical communications: Conduct technical exchanges with us, provide detailed requirements, and understand our production capabilities, technical strength, and past project experience.

Determination of Solution: Both parties reach an agreement on technical details, delivery time, price, etc., forming a preliminary technical proposal and quotation

CONTRACT SIGNING

Contract negotiation: After both parties reach an agreement on the technical proposal and quotation, the contract negotiation stage begins, clarifying terms such as delivery time, quality standards, payment methods, and after-sales service.

Formal signing: Sign a formal procurement contract to ensure the rights and interests of both parties are protected

FINAL DESIGN AND PRODUCTION PREPARATION

Detailed design: According to the contract requirements, carry out detailed design of the power transformer, including drawings and dimensional design of components such as coils, insulation parts, iron cores, and oil tanks.

Material procurement: Procure high-quality raw materials such as silicon steel, copper/aluminum wires, insulation materials, etc. to ensure product quality.

Production preparation: Preparation work before production, including equipment debugging, personnel training, production plan formulation, etc

MANUFACTURING PROCESS

Insulation accessories: Cut the insulation material into required shape and size, perform moisture-proof treatment and other processes.

Oil tank: Cut steel plates into various parts of the oil tank and oil storage components, and perform welding, rust removal, painting and other processes.

Iron core production: Stack the silicon steel sheets into an iron core, install a pull plate and shield, and perform iron core testing and other processes.

Coil production: According to the drawing requirements, select appropriate wire specifications and turns, make the high voltage and low voltage coil windings, and perform wire welding, insulation, coil testing and other processes.

FACTORY TESTING

Assembly and testing: Assemble the iron cores, coils, and other insulation components together for semi-finished product testing, body drying, after that, the active parts will be put into oil tank with oil injection, and leakage testing, hot oil circulation, and static discharge will be proceeded.

Finally, perform a factory test, normally routine test and optional type test and special test according to requirements listed in contract to ensure the product performance meets the requirements.

DELIVERY

Packaging and Transportation: Packaging the product to prevent damage during transportation. Generally, we fix the main body of power transformer in wooden case and for transportation to ensure safe arrival at the destination. For large size main body of power transformers, we have professional solutions for transportation too.

AFTER SALES SERVICE

Our product warranty lasts up to 24 months. After delivering the product to the customer, we will provide necessary technical support of installation guidance. Emails, phone calls, video guide, and on-site guidance are all optional.

Chief Introduction Of Power Transformers

Definition:A power transformer is a static device that transforms electrical energy between two or more circuits through electromagnetic induction. It consists of two or more coils of insulated wire wound around a core made of magnetic material. The primary coil receives electrical energy at one voltage level, and the secondary coil delivers it at a different voltage level.

Key Components

Core: Usually made of laminated iron or steel, the core provides a low-reluctance magnetic path for the transformer. It enhances the efficiency of energy transfer by minimizing magnetic flux leakage.

Windings: The primary and secondary coils, or windings, are insulated conductors wound around the core. The number of turns in each winding determines the voltage ratio between the input and output.

Insulation: To prevent electrical breakdown and ensure the safe operation of the transformer, insulating materials such as oil-impregnated paper, pressboard, and synthetic materials are used.

Tank: The transformer is housed in a tank filled with insulating oil to dissipate heat generated during operation and to provide additional insulation.

Functionality: Step-up and Step-down Voltage Transformation:Step-up Transformer: Increases the voltage from the primary winding to the secondary winding.Step-down Transformer: Decreases the voltage from the primary winding to the secondary winding.

Power Transfer: Transforms electrical power at a specific voltage and current level in a way that minimizes energy losses.

Isolation: Provides electrical isolation between the primary and secondary circuits for safety and to avoid ground loops.

Types Of Power Transformers

Distribution Transformers: Used in distribution networks to supply lower voltage to end-users.

Power Transformers: Used in power transmission systems to step up or step down voltage levels over long distances.

Instrument Transformers: Designed for use in measuring instruments and protective relays to scale down high voltages and currents.

Yawei transformer is a professional manufacturer of power transformers for over 30 years. It has more than 50 engineers and technical personnel. More than 1000 employees, covering an area of 240,000 square meters. It can produce both oil-immersed and dry type power transformer. High voltage power transfer, Distribution transformer, Single phase transformer, Three-phase transformer, Pad mounted transformers, pole-mounted transformer. Our machine haved passof UL, EC, IEC,CNAS,SA,IEEE,ISO9001:2000 quality system certification. It can meet IEEE/ANSI/DOE/CSA and IEC standards. transformers have at least two-year warranty. OEM and ODM accepted. Warmly welcomed to check with our factory.

Quality Standards Of Product

Quality management system GB/T 19001-2016 ISO 9001: 2015

The operation of the whole YAWEI system is strictly controlled and managed. This ensures the quality of products and material in all stages, from receiving customer requests to design, materials, production, installation, testing, packaging, delivery, after-sales, all of which operate under strict and logically linked processes.

Certificate of compliance of UL and CUL

YaWei pad mounted transformer have been evaluated by UL in accordance with the U.S and Canada Standard(s). Our transformer certified by UL based on Canadian standards (CSA standards) .

Accreditation certificate CE

Standard: EN 60076-1:2011.EN 60076-2:2011EN 60076-14:2013 confirms that YAWEI technical quality meets the requirements of all specific international standards for testing and calibration laboratories. All YAWEI products are fully tested in a qualified testing room before leaving the factory, ensuring stable quality and providing absolute peace of mind for customers.

Characteristics Of Yawei Power Transformer

Cover complete production line of transformer from winding wire, silicon sheet slitting and rolling, transformer oil tank producing and power transformer R&D,testing, installation and production.

Yawei automatic insulation wire wrapping line.Yawei has automatic, horizontal, vertical and manual winding lines comes up to different capacity request.

Winding on the primary and secondary windings has an excellent design structure to help the machine operate effectively.

Yawei transformer oil tank casting workshop. Professional work and team for different mold requirements.

Yawei transformer oil tank casting workshop. Professional work and team for different mold requirements.

Yawei configuration fin/ radiator producing workshop.

Yawei transformer front cabinet workshop

Transformer General Technical Parameters

110kv Three-phase duplex winding power transformer on load changer | ||||||

Rating | Voltage Combined | No Load Loss | Load Loss | No Load current | Short-circuit impendance | |

HV | LV | |||||

6300 kVA | 110kV ±8

115kV ±8 | 6.3kv | 10 | 36 | 0.8 | 10.5 |

8000 kVA | 12 | 45 | 0.8 | |||

10000 kVA | 14.2 | 53 | 0.74 | |||

12500 kVA | 16.8 | 63 | 0.74 | |||

16000 kVA | 20.2 | 77 | 0.69 | |||

20000 kVA | 24 | 93 | 0.69 | |||

25000 kVA | 28.4 | 110 | 0.64 | |||

31500 kVA | 33.8 | 133 | 0.64 | |||

40000 kVA | 40.4 | 156 | 0.58 | |||

50000 kVA | 47.8 | 194 | 0.58 | |||

63000 kVA | 56.8 | 234 | 0.52 | |||

110kv Three phase three winding power transformer on load changer | ||||||

Rating | Voltage Combined | No Load Loss | Load Loss | No Load current | ||

HV(kV) | MV(kV) | LV(kV) | ||||

6300 kVA | 110kv±8

115kv±8

| 35kv | 6.3kv | 12 | 47 | 0.95 |

8000 kVA | 14.4 | 56 | 0.95 | |||

10000 kVA | 17.1 | 66 | 0.89 | |||

12500 kVA | 20.2 | 78 | 0.89 | |||

16000 kVA | 24.2 | 95 | 0.84 | |||

20000 kVA | 28.6 | 112 | 0.84 | |||

25000 kVA | 33.8 | 133 | 0.78 | |||

31500 kVA | 40.2 | 157 | 0.78 | |||

40000 kVA | 48.2 | 189 | 0.73 | |||

50000 kVA | 56.9 | 225 | 0.73 | |||

63000 kVA | 67.7 | 270 | 0.67 | |||

Transformer Shipping

Yawei Transformer boasts over 30 years of experience in transformer manufacturing and export, making them highly adept in the intricacies of transformer packaging and transportation.

In the case of 110KV 230 kV power transformers, with dimensions exceeding three meters in height and weight surpassing 50 tons, it is common practice to disassemble high-voltage bushings, radiators, fans, and other accessories. Subsequently, the transformer body and these removable components are shipped separately.

Yawei Transformer employs specialized open-top containers to securely packing the transformer body, while the detachable accessories are meticulously packed in wooden cases, ensuring their safe transport via a separate container.

75000KVA power transformer loading at port

Overseas Project Cases

This 40MVA 110KV power transformer is manufactured and tested by Yawei, it is shipped to Armenia and installed on site.

This 16000kva 110kv power transformer is operating continuously well in Uzbekistan.

FAQ

- Q: 1.What are 4 types of transformers?

A: Transformers can be categorized in various ways based on their function, construction, and application. Here are four common types of transformers:

Power Transformers: These are used in transmission networks for stepping up or stepping down the voltage. They are typically found in power plants, electrical substations, and at various points in the power grid. Power transformers are designed for high-voltage and large-capacity applications, making them suitable for long-distance electricity transmission.

Distribution Transformers: These transformers are used to step down the voltage for distribution to residential or commercial users. They are smaller in capacity compared to power transformers and are designed for efficiency at the lower load levels typically found in distribution networks. These are the transformers commonly seen on utility poles or in ground-level boxes in neighborhoods. Isolation Transformers: An isolation transformer is designed to decouple two circuits, allowing AC power to be taken from one device and fed into another without electrically connecting the two circuits. These transformers provide electrical isolation and are often used for safety, to prevent shock, and in sensitive equipment where a clean power supply is necessary.

Instrument Transformers: These transformers are used in conjunction with measurement and protective devices. They include current transformers (CTs) and potential transformers (PTs). CTs are used for measuring current and protecting the safety of the grid, and PTs are used for measuring voltage. These transformers are essential for the accurate monitoring, control, and protection of the power supply system. Each type of transformer plays a critical role in the generation, transmission, and distribution of electrical power, ensuring both safety and efficiency in the electrical grid. - Q: 2.What is the difference between a power transformer and a normal transformer?

A: The term "normal transformer" isn't a technical classification in electrical engineering, so I'll assume you're referring to a generic transformer or more specifically, a distribution transformer. The main differences between a power transformer and a distribution (or a typical) transformer are their function, size, capacity, and location within the electrical power system:

Function and Application:

Power Transformers: These are used in the transmission network of the electrical grid. Their primary function is to step up the voltage from power stations for high-voltage long-distance transmission and then step it down at the substation for distribution.

Distribution Transformers: These transformers are used in the distribution network. They further step down the voltage from the level used in the distribution lines to the levels used by the end consumer, like residential, commercial, or small industrial users. Capacity: Power Transformers: They are designed for high capacities, often ranging from several tens of MVA (Mega Volt Amps) to several hundred MVA. They are built to handle large power loads and are efficient at high load conditions.

Distribution Transformers: These have a much lower capacity, typically ranging from about 5 kVA to a few MVA. They are optimized for efficiency at the lower load levels typical in distribution networks.

Size: Power Transformers: Due to their high capacity, power transformers are significantly larger and heavier. They are usually installed in power plants and substations. Distribution Transformers: They are smaller and can be easily spotted mounted on utility poles or placed on ground-level pads in residential and commercial areas.

Operational Load: Power Transformers: These are designed to operate close to full load and are most efficient under such conditions. Distribution Transformers: They are designed to operate efficiently at lower load levels since the demand in distribution networks can vary significantly throughout the day.

Cooling Systems: Power Transformers: Often equipped with more complex and robust cooling systems due to their size and power handling.

Distribution Transformers: Typically have simpler cooling systems. In summary, power transformers are key components in the high-voltage transmission network, handling large amounts of power, while distribution transformers are used in the lower voltage distribution network, directly serving end users with smaller power requirements. - Q: 3.Is there a difference between a transformer and a power supply?

A: Yes, there is a significant difference between a transformer and a power supply, as they serve different functions in electronic and electrical systems:

Transformer:

Function: A transformer's primary function is to step up or step down voltage in alternating current (AC) electrical circuits. It does not change the type of current (AC to DC or vice versa) or regulate the output voltage under varying load conditions. Construction: It consists of two or more windings (coils of wire) wrapped around a magnetic core. When AC voltage is applied to one winding (primary), it creates a varying magnetic field that induces a voltage in the other winding (secondary). Use Cases: Transformers are used in power distribution systems, in power adapters for small appliances, and as components in various electronic devices.

Power Supply:

Function: A power supply is a broader term that encompasses devices or circuitry that supplies power (voltage and current) to an electrical load. Its main function is to convert electric current from a source to the correct voltage, current, and frequency to power the load. This includes AC to DC conversion (as in adapters for electronic devices), DC to DC conversion, or even AC to AC conversion with different characteristics. Components: A power supply often includes a transformer as one of its components, but it also contains other elements like rectifiers (for AC to DC conversion), filters (to smooth out the output), and regulators (to maintain a constant output voltage or current). Use Cases: Power supplies are used in a wide range of applications including computer power units, battery chargers, LED drivers, mobile phone chargers, and various electronic gadgets. In summary, while a transformer is a component that changes the voltage level of AC power, a power supply is a more complex device or system that not only can include a transformer but also performs additional functions such as converting and regulating power to suit the needs of an electrical device or system. - Q: 4.What are the advantages of a power transformer?

A: Power transformers, essential components in the electrical power distribution network, offer several key advantages: Voltage Conversion: Power transformers enable the efficient transmission of electricity over long distances by stepping up voltage levels for transmission (reducing energy loss) and stepping them down for safe, practical use in residential, commercial, and industrial settings. Energy Efficiency: At high voltage levels, transformers allow electricity to be transmitted with minimal loss of energy. This efficiency is crucial for reducing operational costs and environmental impact.

Safety and Isolation: Transformers provide an effective means of isolating different parts of the electrical system, which enhances safety. By stepping down the voltage to safer levels, they prevent the risks associated with high-voltage power transmission. Customization and Versatility: Power transformers can be designed and built to meet specific requirements, such as different voltage levels and capacities, making them versatile for various applications in the power grid.

Reliability and Longevity: These transformers are known for their reliability and long service life. They are built to withstand harsh operating conditions and maintain functionality over many years, reducing the need for frequent replacements. Facilitates Long-Distance Transmission: The ability to transform voltage to very high levels makes it feasible to transmit power over long distances, connecting power plants to distant consumption areas with reduced energy losses.

Improved Power Quality: Power transformers can help in improving the quality of power supply by reducing voltage fluctuations in the distribution network.

Economic Benefit: By enabling efficient long-distance transmission and reducing energy losses, power transformers contribute to the economic efficiency of the power distribution network. These advantages make power transformers indispensable in modern electrical distribution systems, ensuring efficient, safe, and reliable delivery of electricity from generation facilities to end-users. - Q: 5.Why use transformer in power supply?

A: Using a transformer in a power supply is crucial for several reasons, especially in AC (Alternating Current) power supplies: Voltage Transformation: Transformers can step up or step down the voltage level. This is essential for bringing the high-voltage electricity from the mains supply down to a safer, more usable level for various electronic devices and appliances.

Electrical Isolation: Transformers provide electrical isolation between the input and output, which enhances safety. This isolation is important to protect the user and the device from potential electrical faults in the power grid.

Power Conditioning: In some designs, transformers can aid in improving the quality of the power by attenuating spikes and electrical noise present in the input supply, thereby protecting sensitive electronic components.

Compatibility with Rectification: Many electronic devices require DC (Direct Current) power, but the supply from the grid is AC. Transformers in AC power supplies can adjust the voltage level before rectification (conversion of AC to DC), allowing for efficient and tailored DC power supply design.

Enabling Voltage Regulation: After the transformation process, it becomes easier to regulate the voltage to the required stable level using additional components like voltage regulators, ensuring a constant and reliable power supply to the device.

Cost-Effective and Reliable: Transformers are relatively simple, robust, and cost-effective components. They have a long lifespan and require minimal maintenance, making them ideal for use in power supplies.

Standard Compliance: For safety and performance reasons, many electronic devices must comply with regulatory standards that often require the use of transformers to ensure a safe level of voltage and isolation from the mains supply.

In summary, transformers in power supplies are fundamental for adjusting voltage levels, ensuring safety through electrical isolation, and providing a reliable and compliant power source for a wide range of electronic devices and appliances.

- Q: 6.What does a transformer do in simple terms?

A: In simple terms, a transformer is a device used to change the voltage of electricity in a power system. It works with alternating current (AC), which is the type of electricity commonly used in homes and businesses.

Here's a basic explanation of what a transformer does: Steps Up or Steps Down Voltage:

A transformer can increase (step up) or decrease (step down) the voltage of electricity. For example, it can take high-voltage electricity from power lines and reduce it to a lower voltage that is safe to use in your home.

Works Through Electromagnetic Induction: Inside a transformer are two sets of coils (wires) wrapped around a core. When electricity flows through one coil (called the primary coil), it creates a magnetic field. This magnetic field then creates (induces) electricity in the second coil (called the secondary coil). This process doesn't involve any moving parts; it all happens due to the principles of electromagnetism. Doesn't Change the Power: While a transformer changes the voltage, it doesn't change the overall power of the electricity. If it steps down the voltage, the current increases proportionally, and vice versa. This means the product of voltage and current (which equals power) remains the same, minus some small losses due to inefficiency. In everyday life, transformers are used in many applications, from the large ones in power stations and on power poles to small ones in electronic devices like chargers and power adapters. They are essential for safely and efficiently transmitting and using electricity. - Q: 7.How do you connect a power supply to a transformer?

A: Connecting a power supply to a transformer involves several steps and considerations to ensure safety and proper operation. Here's a general guide on how to do it:

Safety First Disconnect Power: Before beginning any work, ensure that all power sources are disconnected.

Safety Equipment: Wear appropriate safety equipment, such as gloves and eye protection.

Understand Specifications: Be sure to understand the specifications of both the power supply and the transformer, including voltage, current, and power ratings.

Identify Transformer Terminals Primary Winding: This is the side of the transformer that will connect to the power supply. The primary winding is designed for a specific voltage and frequency (e.g., 120V, 60Hz in the US or 230V, 50Hz in Europe).

Secondary Winding: This is the output side, where the transformed voltage will be available. Connecting to the Power Supply Prepare the Wires: Strip the ends of the wires that will connect to the transformer's primary terminals.

Connect to Power Supply: Attach the power supply wires to the primary terminals of the transformer. Make sure the connections are secure and insulated to prevent any short circuits. The power supply voltage must match the voltage rating of the transformer's primary side.

Grounding (if applicable): If the transformer has a grounding terminal, ensure it is properly grounded for safety. After Connection Check Connections: Double-check all connections for correctness and safety. Test for Functionality: Initially power on the system with a circuit breaker or protection device in place to safeguard against any short circuits or wiring mistakes.

Additional Considerations Polarity (if applicable): In some cases, especially with DC power supplies or certain types of transformers, the polarity of the connections might be important. Fusing or Circuit Protection: Always have appropriate fusing or circuit protection in place.

Compliance with Electrical Codes: Ensure all work complies with local electrical codes and regulations. Professional Assistance: If you are not experienced with electrical installations, it is advisable to seek help from a qualified electrician or technician. Special Cases Transformers in Electronic Circuits: In electronic projects, transformers are often used for converting AC mains voltage to lower AC voltages. After transformation, further conversion to DC (using rectifiers) and regulation might be needed, depending on the application.

Variable Power Supplies: If using a variable power supply, ensure the voltage does not exceed the transformer's maximum primary voltage rating. Note: The above steps are a general guide. The actual process can vary depending on the specific type of transformer and power supply. Always refer to the YAWEI's instructions and safety guidelines. - Q: 8.How long does it take to fix a power transformer?

A: The time it takes to repair a power transformer can vary widely depending on several factors.

There isn't a one-size-fits-all answer, but here are the key elements that influence the repair time:

Nature and Extent of the Damage: Minor issues like fuse replacements or connections might be fixed within hours. However, significant damage, such as winding faults or core damage, can take days or even weeks to repair.

Availability of Parts: If the repair requires replacement parts, the time depends on their availability. Common parts might be on hand, but unique or rare components might need to be ordered, which can extend the repair time.

Type of Transformer: Smaller distribution transformers are generally quicker to repair or replace than larger power transformers. Power transformers, due to their size, complexity, and critical role in the electrical grid, require more time and expertise to repair.

Location and Accessibility: Transformers in remote or difficult-to-access locations can take longer to repair. Weather conditions and terrain can also impact the repair time. Safety and Testing Procedures: Safety is a primary concern. Repairs must be conducted following strict safety protocols. After repair, transformers typically undergo thorough testing before being put back into service, which adds to the total time.

Expertise and Manpower: The availability and skill level of technicians play a role. Having experienced professionals can expedite the process, whereas a lack of skilled personnel can delay it.

Regulatory Compliance and Inspections: Depending on the region, repairs may need to comply with specific regulations, and inspections might be required before the transformer can be re-energized, adding to the timeframe.

In a general sense, simple repairs can take a few hours to a day, while complex issues or major damages in large transformers can take several weeks. In cases where repair is not feasible or cost-effective, replacing the transformer might be a better option, and the time frame for replacement would include procurement and installation of the new unit. - Q: 9.What does an electrical transformer look like?

A: An electrical transformer typically has a distinct appearance, which can vary depending on its type (such as power or distribution transformer) and whether it's for use in a residential, commercial, or industrial setting.

However, common characteristics include:

Metal Housing or Casing: Transformers are usually enclosed in a metal housing, which protects the internal components and provides safety to the public.

The casing might be rectangular or cylindrical. Bushings or Terminals: These are the points where the input (primary) and output (secondary) wires connect to the transformer. They are often visible as protruding insulators (which can be porcelain or other materials) with conductive connectors on the top or sides.

Cooling Fins or Radiators: Larger transformers, especially those for higher capacities, often have external fins or radiators. These are part of the cooling system designed to dissipate the heat generated during operation.

Nameplate or Label: Transformers typically have a nameplate or label indicating key specifications like voltage, current, capacity (in kVA or MVA), and manufacturer details.

Size and Shape: Distribution transformers, commonly seen on electrical poles, are smaller and can be cylindrical (drum-like) or box-shaped. Power transformers, used in substations and industrial plants, are larger and typically box-shaped or rectangular.

Color: They are often painted in a standard color like grey, green, or blue, which is chosen for its visibility and to blend in with the surroundings or to meet regulatory standards.

Mounting Configuration: Pole-mounted transformers are affixed to utility poles, usually at a height, while pad-mounted transformers are placed on the ground on a concrete pad and are often encased in a tamper-proof cabinet.

Sound: Transformers may emit a low humming sound during operation, due to the vibration of their components under the influence of the magnetic field. In residential areas, transformers are usually smaller and might be pole-mounted or in small ground-level boxes. In commercial or industrial settings, they tend to be larger and are more likely to be part of a substation setup. - Q: 10.Is a transformer a power conditioner?

A: A transformer and a power conditioner serve different, albeit sometimes overlapping, functions in managing electrical power. It's important to understand their distinct roles:

Transformer Primary Function:

A transformer's main role is to step up or step down voltage in an electrical circuit. It works exclusively with alternating current (AC). How It Works: It operates on the principle of electromagnetic induction, with two or more windings around a magnetic core. When AC voltage is applied to the primary winding, it induces a different voltage in the secondary winding, depending on the winding ratio. Use Cases: Transformers are widely used in power transmission and distribution to adjust voltage levels. They are also found in various electrical devices for voltage adjustment.

Power Conditioner Primary Function:

A power conditioner is designed to improve the quality of the power that is delivered to electrical load equipment. Its main goal is to provide a clean and stable power supply by mitigating issues like voltage irregularities, noise, and spikes in the power line.

How It Works: Power conditioners use a combination of technologies like surge protection, noise filtering, and voltage regulation. Some advanced models may also include transformers as part of their circuitry.

Use Cases: They are commonly used with sensitive electronic equipment, where even minor power quality issues can cause malfunctions or damage. This includes computers, audio/video equipment, laboratory instruments, and other high-precision devices. Overlapping Functions Isolation: Some transformers (isolation transformers) provide electrical isolation along with voltage transformation, which can help in reducing line noise and minor surges – a function similar to basic power conditioners. Conclusion While a transformer can indirectly contribute to power conditioning (especially in the case of isolation transformers), it is not a power conditioner in the strict sense. A power conditioner offers a broader range of power quality solutions, often including but not limited to the functions of a transformer.

评价

目前还没有评价